I’ve been working with Flash NAND for nearly two decades and have had a very close-up look at the xLC flash drive transition as it shifts to the below.

Back around 2008, there were a lot of small enterprise SSD vendors who were looking to take advantage of the emerging enterprise flash trend. These solutions typically utilized single layer cell (SLC) NAND and new exotic architectures such as “over provisioning” and new ways to layout data across the NAND chips to reduce wear and increase performance. It was an exciting and very fast paced time.

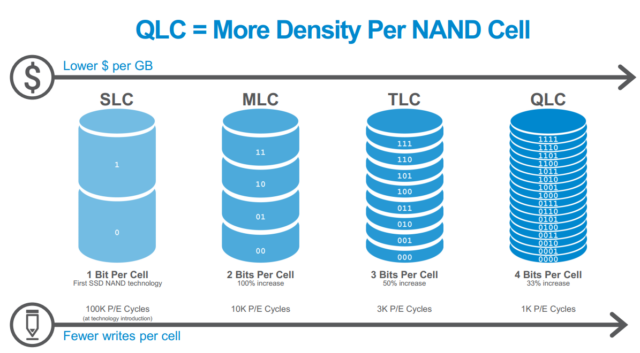

SSD technology has quickly evolved from single bits per cell (SLC), to two bits per cell (MLC), then to three bits per cell (TLC), all in a matter of a few years. Also, very importantly as we saw the volume of enterprise SSDs grow, the cost of these devices reduced significantly.

Why did the transition happen so quickly? Three reasons:

- SSD technology improved and hardened very quickly

- Industry flash production supply quickly shifted to MLC and later to TLC

- Most importantly, a larger cost advantage for the transition

Let’s focus on that last point. The real reason to move to more bits per cell historically was around economics. Moving from SLC to MLC dropped the cost of production roughly in half. Moving to three bits eventually gave an additional 50% density for the same cost. I deliberately said “eventually” because when new technologies emerge, the NAND vendors need to deal with issues like wafer yields, ramping up production, testing performance, monitoring quality and maintaining reliability.

With this reduction in costs came tradeoffs. With each additional bit added, there is a reduction in NAND endurance as well as NAND latencies (i.e. SSD performance). When Dell Technologies released one of the industry’s first TLC based all-flash systems, we made sure that the systems could easily ensure more than five years of heavy enterprise use from a reliability perspective. The significant reduction in cost more than made up for any performance tradeoffs. Very quickly we saw our high-performance drive business (15K HDD) drop to zero and customers make a very quick pivot to our all-flash systems.

The industry is now looking at QLC (quad-level cell) as the next big inflection point in all-flash systems. The reality is the shift to QLC is a much smaller, more transitional step in lowering the cost of storage. This is especially true as I write this in 2021 from a Dell technologies lens. As one of the world’s largest end-to-end IT suppliers, we gain a huge competitive advantage by allowing us to use our massive supply chain to purchase at scale and provide our customers with the best economics – better than QLC in many cases.

We’ve been looking at QLC technology before some of our competitors existed. There really isn’t any magic for integrating QLC devices into our systems. So why haven’t we?

It’s simple. Any “potential” saving that we could give to our customers, are more than offset by the reductions in endurance and performance at the device level. I can’t give specific values, but the cost advantages with QLC are currently between zero and low single digit percentages. That’s right, at least for Dell Technologies given our huge supply chain, there is little advantage to jumping to these flash transitions too quickly.

Right now, we are looking at exploring QLC especially as it approaches Gen 2, which promises important and needed improvements in reliability and performance. We will be there with solutions that address this when the time is right so that Dell Technologies support and our customers have the best possible experience.

After all, it’s the experience, not the drives that support our customer’s objectives to innovate with data.