A Dell Technologies factory uses a management software system to plan and schedule the orders it will build in the next few hours. It then analyzes on-site inventory to determine what components to have delivered from nearby supply logistics centers, places the order, confirms delivery and updates inventory books.

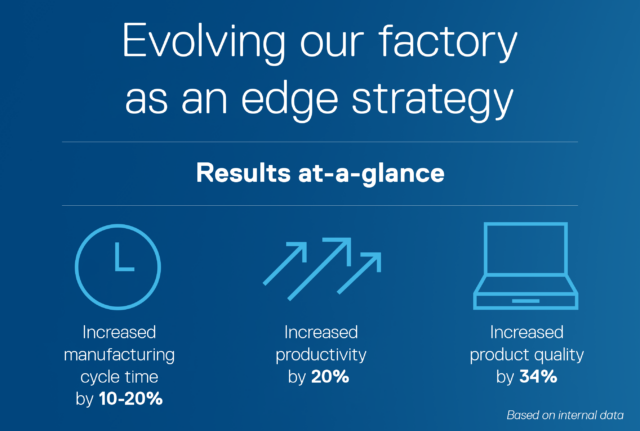

Planning, scheduling and inventory are just some of the decisions Dell has shifted to its individual factories from what used to be generated by our corporate system, far outside the four factory walls. Our evolving factory as an edge strategy has reduced our manufacturing cycle time by 10-20 percent, upped productivity by 20% and increased product quality by 34%.

Our smart strategy is built on the foundation that we have been working to streamline and standardize our factory processes for years, as well as modernize and virtualize our factory infrastructure using our own technologies, in particular VxRail.

This not only laid the groundwork for making more and more decisions at the edge, but also has given us the flexibility to react to market fluctuations, weather events and other factors.

Increasing smart factory capabilities at the edge is more critical than ever to be able to react to today’s dynamic manufacturing environment.

A Transformation Journey to the Edge

The edge is where data is acted on near its point of creation to generate immediate, essential value.

Dell began moving toward factory as an edge by working to consolidate and standardize our company-owned factory operations, with the goal of having every factory run on the same application footprint.

Before 2009, our factories were dependent on our corporate systems to do planning, inventory management and processes. One reason for this was the lack of common operating processes and standards.

Like many manufacturing operations across the industry, our factories varied widely in how they operated. Each had evolved over time with respect to regulation, local requirements and factory management’s approach to running the business. Each had a different set of applications. No two factory IT footprints were the same.

Dell created a Manufacturing Product Team to tackle streamlining factory operations across all our unique facilities. That meant aligning business processes and agreeing on what capabilities were needed at regional and global levels, based on conversations with each location. Not all innovations made sense in all locations.

We had to enable a comprehensive set of capabilities that allowed factory managers to use what met their individual needs. In some instances, this was automation. For others, it was standardized manual processes based on collaboration with business stakeholders.

Once we established our priorities, the team standardized a single management solution that would meet those needs, effectively reducing our factory applications from 90 to one. Deploying the new solution was challenging. We had to train every operator in every factory on utilizing a new set of products and implementing an entirely new set of processes.

It was a crucial step towards as an edge strategy. Our factory processes and capabilities had to be consistent in order to quickly react to changing market demands. Once we created a base IT footprint across our factories, the team could then begin bringing more decisions into the factory.

At the same time we implemented the latest version of our factory management solution, we started enabling a factory as an edge model, beginning with the production planning process.

Adding inventory to the edge capabilities was a logical next step so we could get the most out of inventory control solutions, both in corporate and in our updated factory management tool. We are now bringing more and more decisions into the factory.

It’s All About an Agile Factory Ecosystem

Dell’s factory as an edge strategy is part of a broader effort to create a factory ecosystem where we can order, build and ship from anywhere in the face of a rapidly changing manufacturing climate.

To that end, Dell has digitally transformed our factories using modern cloud infrastructure built on VxRail that enables server virtualization and delivers cloud-like capabilities.

We initially had many powerful physical servers in our factory data centers to handle extensive compute power for things like planning, real-time interactions with the conveyor belts, and scanning and weighing capabilities.

We replaced more than 60 racks of physical servers with a single VxRail rack in each factory, reducing energy consumption by approximately 50% and freeing up data center space. The private cloud environment has delivered increased flexibility, agility, speed and lets our factories automatically scale up or down as needed. While we considered using a public cloud environment, we determined that a custom on-prem solution better suited our needs for speed, access, time to resolution and supportability.

The flexibility we gained is crucial. For example, if we find we have capacity limitations in one area, we now can rapidly shift to a factory in another region.

It takes a comprehensive strategy, including technology modernization, standardization and factory as an edge to gain the agility to keep pace in today’s manufacturing world. More than that, it takes working with your factory stakeholders to set up processes and practices that make sense for their individual needs.

The bottom line is that by getting all of these things working together, you will be able to react quickly to the changing dynamics in the industry to gain the most value from your transformation.

Keep up with our Dell Digital strategies and more at Dell Technologies: Our Digital Transformation.