Autumn Egnatuk is a typical four-year old girl. She loves gymnastics, her beloved doll “Rainbow” and the Disney movie Frozen. She’s curious, full of energy and enjoys playing with friends and her younger sister. The fact that she was born without a left hand doesn’t seem to slow her down. She can do everything her preschool classmates can – and then some!

Autumn Egnatuk with her parents Ronnie and Sarah

After she was born, Autumn’s parents Ronnie, an OEM Enterprise Product Specialist at Dell, and his wife Sarah researched everything they could about limb differences and prosthetics. Most guidance recommended starting early. However, their initial attempts to get a prosthesis for Autumn were met with frustration and disappointment.

The Egnatuks secured an appointment at a world-renowned hospital that caters to people with amputations and limb differences, hoping for assistance and a long-term plan for Autumn. Unfortunately, they were told that because Autumn was meeting age-appropriate developmental milestones, she didn’t need a prosthesis. Insurance doesn’t typically cover them for children, despite research showing multiple benefits. A prosthesis not only increases functionality for children with limb differences, but it can help build self-confidence, which is critical for kids during this period of their lives.

Children like Autumn who have dysmelia (the term for all types of congenital limb differences) not only want to blend in with their classmates and friends, but they want – and deserve – the increased functionality that a prosthesis can bring. Determined, Ronnie and Sarah continued their quest and finally found a company in Houston, TX, that had experience in pediatrics and specialized in upper limb prosthetics. They began the tedious process of filing for medical necessity with their insurance company. After seven long months, Autumn was finally approved for a passive prosthesis device. It looks like a doll’s hand but does not function. It was a good start, but not a long-term solution for an energetic and growing little girl.

3D Printing Prosthesis

In September 2018, an article on Dell’s internal website caught Ronnie’s eye. Tara Sawyer’s story “Changing Lives Through 3D Printed Prosthetics,” described Dell employee Keith Dyer’s daughter Phoebe, and her journey to getting a 3D printed arm. The Dyers live in the UK, and like Autumn, 7-year-old Phoebe has dysmelia. The Dyer family worked closely with Deloitte Digital to get 3D printed hands for Phoebe. Phoebe loves her prosthesis, and even got to show off her custom Manchester United hand to the players at a home game!

Ronnie was intrigued and reached out to Phoebe’s dad Keith to learn more about their process. He wondered if this process might be something they could look in to for Autumn back home in Texas. Around the same time, Seamus Jones, who works in Technical Marketing for Dell, was also inspired by the story and reached out to Keith to see how our team in Round Rock might be able to help locally. Seamus knew that we had 3D printers on site because our OEM team often develops custom solutions for customers. We have the design (CAD) and 3D printing expertise to accomplish a project like this. Keith put him in touch with Ronnie, and the “Autumn Project” in Texas was soon underway!

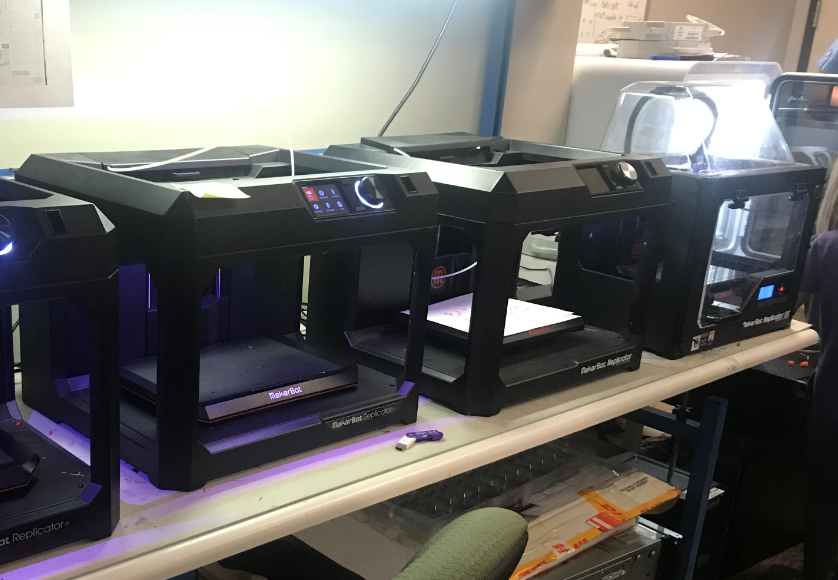

3D Printing

It takes approximately 14 hours to print a child’s size hand using 3D printer, and another four+ hours to assemble. But the time and cost are minimal compared to a traditional prosthetic.

3D Printers in Round Rock, TX

For the Autumn Project here in Round Rock, Seamus coordinated with engineers Ric McKinney and Karl Hamand, who readily agreed to help. Normally, most of the 3D printing done onsite is industrial black. But they wanted to give Autumn the opportunity to customize hers, so the PowerEdge Product Marketing team agreed to sponsor the ABS and PLA material in additional colors. Autumn chose a yellow and orange version, and a light blue and white “Frozen” version.

Before long, the team had created two brand new hands for her:

The Hand Off

January 18, 2019 was the big day – time to present Autumn with her new hands. The Egnatuks traveled from their home outside of Houston, TX, and Keith was in town from the UK.

Seamus brought donuts and toys to help Autumn feel comfortable (he has daughters of his own, and knows sugar is often a quick way to make friends with a little one!). The most important thing was that she felt comfortable and had time to try on and get used to her new hand. After all, this entire project was about her.

As you can see, the hands were a hit:

Autumn trying on her new prosthetic while Keith Dyer shows her pictures of his daughter, Phoebe

Seamus Jones helps Autumn get familiar with her new hand

Autumn throwing a ball with her mom Sarah’s encouragement!

The Autumn Project Team

Adults: Seamus Jones, Brian Blossom, Sarah Egnatuk, Ronnie Egnatuk, Keith Dyer, Karl Hamand

Children: Autumn Egnatuk, Stella Hamand, Andi Egnatuk

Not Pictured but played an integral part: Chad Fenner, Scott Johnson, Andy Wilks

Soon after, Ronnie followed up with the Autumn project team: “It has been two weeks since Autumn received the additional hands form Dell and we could not be more impressed with how proud she is to wear them and show them to her family and friends. We are truly grateful.”

This is a wonderful example of how collaboration, innovation and technology can make a massive impact and truly change lives.

As Seamus explained “If we can make a difference in a child’s life, by providing greater functionality and most importantly increasing his or her confidence, we want to help. That’s why we do what we do.”

At Dell, we use technology to enable others to reach their full potential. We’re proud to be a part of this project, and as Seamus said, “This is only the beginning.” He is currently in contact with several nonprofit organizations to grow awareness of dysmelia and help both children and adults with limb differences.

For additional information on this project, or if you or someone you know has dysmelia and could benefit from a 3D printed prosthesis, email Seamus Jones at enable@dell.com.

A special thanks to e-Nable and Team Unlimbited for providing the open-source 3D templates both Dell and Deloitte continue to use in building 3d printed arms for children and adults who ask for them. This project is truly an inspiring ‘open source’ team effort.