On January 4, we unveiled the new small but speedy Dell XPS 13. Already winning awards and heralded by outlets like PCWorld for setting the trend for thin, light and small (but mighty).

The team involved in its overhaul are celebrating (rightfully so) and experiencing a bit of nostalgia recounting how we went from idea to reality! I thought you’d enjoy some of the “inside baseball” on the thermal engineering of XPS 13 – a big part of how we made the world’s favorite laptop even better (it’s a little geeky but that’s what makes it cool).

As Jason Evangelho noted in Forbes, “the same material that protects Mars Rover makes Dell’s XPS 13 a better notebook.”

Here’s an excerpt from an email exchange I had with the engineer behind it all: Dell Thermal Engineering Technologist Travis North P.E.

“The material wrapped around the heat pipes is called Aerogel laminate. The material is a silicon aerogel in a ePTFE liner. The liner from GORE (a really cool company – still family owned and killing it in industries from apparel to aerospace and now computing) was critical, allowing us to thin out the product for feasibility use in the PC industry. Dell is first to launch with this material – it has the lowest conductivity known to man. Launching tomorrow, you’ll see a second product with this material – the first with 0.1mm material thickness (thinnest material). Net-net – this allowed for close to a 3C reduction in skin which equates to close to a 4W increase in overall PL1 level performance at steady state.

“Additionally, we’re using our dual ultrathin fan with dual heat pipes, which allowed us to support the full turbo range on R and G as well as elevated sustained levels of steady-state power.”

GORE Thermal Insulation was with us on the big stage at CES today – check it out by watching the replay on our Alienware team’s Twitch channel.

Travis’ manager weighed in, reinforcing:

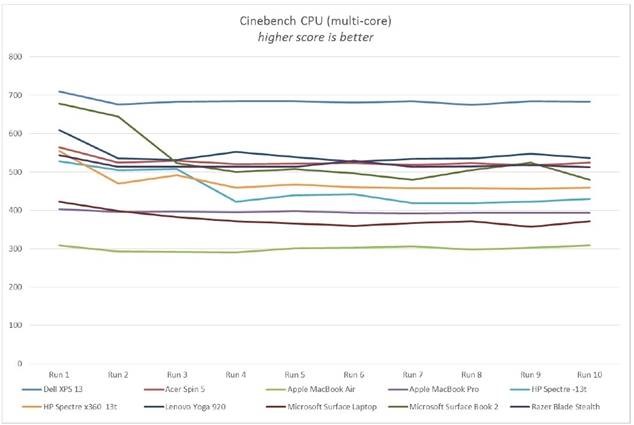

“It (XPS 13) uses a cutting-edge thermal insulator (Silicon Aerogel, NASA technology) with allows us to reduce the skin temperature by 3 degrees. This has been the primary limitation of performance. This gives us a significant boost in sustained performance when you run for a longer duration – can be 15-40%. Most thin systems throttle the performance in minutes – you can see the comparison of our system versus the competition over multiple runs (leads by a mile).”

You can see a chart for comparison below. And if you are curious about what aerogel looks like (I know it’s been keeping you up at night 🙂 ) – here you go.

“So many companies are always abusing the phrase ‘space age technology,'” Evangelho said. “Well, Dell’s definitely backing it up.”

It took time to get here with some failed attempts, but we made it.

In the end, the ePTFE liner from GORE was what was able to encapsulate the silica aerogel while allowing us to achieve thickness sub 0.3mm which was required for our products. The material is almost as light as air and has a Styrofoam type feel.

Join us in congratulating Travis and the team for their innovation and drive. Each and every ingredient innovation is what makes our products the best in the world — and our team even better!