The following is a guest post by Vinesh Narayan, product manager at D-Rev. D-Rev designs and delivers medical technologies that close the quality healthcare gap for under-served populations. Their goal is to shift industries to make world-class healthcare more accessible for all, and Dell is excited to help them achieve that.

************

Last May I got an unexpected email from our partner in China – a prototype of the ReMotion Knee, our prosthetic knee product, had just failed cyclic testing as part of its ISO certification. I say unexpected because it had passed our internal testing and we were confident going into the test lab’s intense testing protocols. The test results meant we had to redesign quickly, on a tiny budget, and fix our product as fast as possible. Not to mention, our CEO Krista Donaldson was headed onto the TED Women stage THAT DAY to talk about how close we were to publicly launching our product. It was not a good morning.

Let me back up. I work at D-Rev, a non-profit medical technologies company focused on the needs of low-income patients. We design and deliver world-class, affordable health technologies and scale our products via the market to maximize global reach and impact. The ReMotion Knee is our fourth product to go to market – it is a prosthetic knee joint for above-knee amputees in low-income countries.

Unlike many devices on the market, the ReMotion Knee is designed specifically for underserved markets – we’ve optimized the design for durability, efficiency, and affordability. Like other knee joints, it lasts 3-5 years, has maximum stability, and a universal adapter design for mass implementation. Unlike other knee joints, it works very well in hot, humid, and dirty environments, like farming and construction where many of our target users work, and costs $80 USD – approximately one-fifth of the cost of equivalent devices. Right now, the ReMotion Knee engineering team is two people – myself, the product manger, and our senior R&D engineer, Michael Hong.

As a result of a fortuitous introduction from the Autodesk Foundation, one of D-Rev’s key supporters, we received a donation of critical equipment from Dell, including three powerful workstations and three laptops. Our engineering team rapidly adopted the equipment to accelerate our internal testing processes – specifically, finite element analysis (FEA) and failure analysis. We affectionately named them Batman, Superman, and Robin.

When the knee prototype didn’t pass the test we had to make quick decisions – we had budgeted for and promised customers, supporters, and our team at D-Rev that we would launch the ReMotion Knee by the end of 2015. We did not want to miss our target.

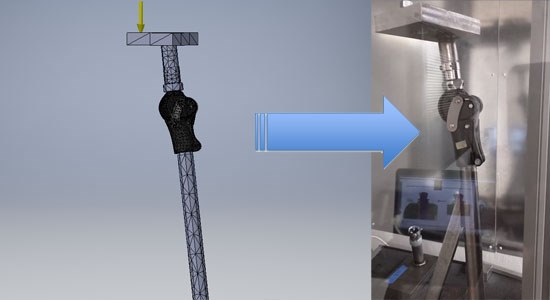

Because of the Dell equipment and Autodesk’s software we were able to use finite element analysis (FEA) to rapidly evaluate hundreds of design changes to addresse the issues that caused the failure. Our team saved days by completing almost everything in a virtual environment, rather than relying on prototyping and testing sequentially. As you know, virtual testing is used to supplement physical testing but can’t replace it. We only had to test the most promising designs from the virtual environment, rather than creating and physically testing each iteration.

On the left, the ReMotion Knee in finite element analysis in Autodesk Inventor, on a 2014 Dell Precision workstation. On the right, the ReMotion Knee in our in-office test fixture.

Prior to using the Dell equipment, D-Rev’s computers couldn’t handle the heavy lifting required to run simulations in Autodesk Inventor – our computers crashed or required hours – to process operations, and as a result we had to outsource all of our FEA analysis. By bringing these tools in house, we were able to complete it ourselves and rely on our vendors, a team we consider trusted partners, to give us a valuable second opinion and design.

In ten weeks we went from cause analysis to explain the test results to starting to test the next version. This was the fastest we had ever made critical design changes to the ReMotion Knee – and we went into testing with higher confidence, thanks to the Autodesk Inventor software and Dell workstations.

We don’t expect all prototypes to pass every test – if they did, we would start asking if our tests were tough enough. We conduct rigorous testing because we believe in only delivering world-class products to all customers, regardless of where they live or their income level. The ReMotion Knee was tested to ISO standards at two different independent testing labs and by over 100 patients in clinics around the world. We know that our patients use prosthetics in extreme conditions. Our testing goes above and beyond so that when the final product ultimately does pass, we can be confident that it will hold up in the real world.

This week, the finished ReMotion Knee passed all of its third-party certification testing, including ISO 10328:2006 standards. We are moving quickly to fulfill more than 700 pre-orders from customers in 17 countries, and deliver the ReMotion Knee to amputees, giving them the tools they need to return to their lives.

Prakash was fit with a prototype of the ReMotion Knee in May 2015 at the Jaipur Foot Clinic.

We’re grateful to Autodesk and Dell for making our final design work possible.

************

Vin joined D-Rev’s ReMotion project after co-designing a low-cost elbow prosthetic in a Stanford University course on medical device design. While a graduate student, Vin gravitated toward the medical device arena because of its direct human impact, and this same passion led him to continue his work at D-Rev. Vin believes that solutions with the highest capacity for positive impact combine organizational sustainability with human benefit. Consequently, he is focused on finding sustainable ways to bring ReMotion prosthetic devices to more people outside of India, where it is currently being fit through clinical trials with the JaipurFoot Organization.

Vin holds a Master’s degree in Management Science & Engineering from Stanford University with a concentration in Entrepreneurial Design, focusing on the design of products and services in startup environments that have a high degree of ambiguity. Prior to Stanford, he studied restorative tendon-transfer surgeries at the Rehabilitation Institute of Chicago and earned his Bachelor’s degree in Mechanical Engineering from the University of Illinois.